Rogers Rod & Cycle[]

Rogers Rod & Cycle is a team made up of three individuals: Brendan Rogers, Katie Parness and Andrew Brown.

Brendan Rogers: a Junior Business Management Major from Winchester, VA. Brendan is the brains and hard labor behind the products of Rogers Rod & Cycle. He is highly skilled in welding, fabrication, and likes to work on American cars.

Katie Parness: a Junior Business Management Major from Frederick, MD. Katie has high levels of skill in Microsoft Office/Excel and takes care of most of the paperwork, photo-feeds, and administrative tasks.

Andrew Brown: a Junior Business Management Major from Richmond, VA. Andrew also takes care of some paperwork and has a great understanding of the business model concept and updates it regularly.

Rogers Rod & Cycle is aspiring to become an LLC that can sell car related products without greater liability. For the sake of MGT 372 we are making engine lift plates that are all-American manufactured and have high weld quality.

- Find our photofeed here: http://keightypee.tumblr.com/

Innovation Questionstorming[]

The number one question leading to our product development was "How can we create a differentiated engine lift plate?" and our answer was an all American made lift plate with extremely high quality welding.

Because of the time restrictions in this course we didn't get to accomplish all of our visions but we had a few ideas:

- For each lift plate sold we would donate a portion to a charity of our choice

- The internet is our primary channel of distribution and sales which is why another idea we had was to create our own website to sell lift plates and future products through

- We also had the idea to create a marketing campaign with guerilla marketing techniques in the sense that we would go to many local car shops and car shows to get our brand and product out in the local community

- Another marketing idea we thought about was to publish ads in car magazines as well as advertising/selling on Craigs List and eBay

Big Idea Hypothesis[]

For American car enthusiasts that need to remove engines with the proper tools, Rogers Rod & Cycle's engine lift plates is a tool that provides a strong, durable, American made solution that ensures safety. Unlike competitors, our engine lift plates are manufactured domestically with American steel. Each lift plate is welded by hand and then tested, ensuring a high quality product.

Key Innovations[]

Our main product differentiation:

Innovations that helped define our product were a higher quality weld on thicker steel in conjunction with an American made product to substitute China/Taiwan manufactured counterparts. Since the tool is designed specifically to lift American-made motors, our customer is likely to value domestically made products. The main problem with this innovation is the end product costs at least 50-100% more than products manufactured overseas. So it is hard to make a sale unless the consumer is quality and origin of manufacture conscious, in other words, sees the value (intangible and tangible) rather than the price.

Early Adopters[]

Right in the beginning we knew our general group of adopters would be people who were DIY'ers that work on their own cars in their personal garages or those who own shops. Our product has a pretty narrow customer pool which made it pretty difficult to sell. The problem that we ran into was that most people who work on cars or own a shop already have engine lift plates. Although those lift plates were a lower quality, they didn't see a reason to re=buy a tool. Because of this, our more targeted customer base was people who greatly valued an all American made product with a higher quality weld that would substitute products made overseas.

We did find that it was easiest to find early adopters through online forums that had people with interests in similar to ours. Our earliest adopter was someone who Brendan reached through a forum who was very enthusiastic about our product and even put in a pre-order to buy one before we had even began building them.

Resources[]

Brendan goes home every weekend to work at a local shop, Clarke County Speed, where he has been working for years. His owner, Oj, allowed him to work on our engine lift plates in his extra time. Although we had to buy a hole saw and all of the metal, having a shop to work on our product was a huge advantage because of the availability of other tools and adequate space for welding.

Metal from MSC Industrial Supply Co.

Time was a resource that was very limited in this project because the shop is located in Winchester, VA and Brendan was only able to work on the weekends when he had no other work to do for his boss. Time also limited the amount of progress we made within the semester. We had hoped to establish our "company" as an LLC due to the high risk of the product's nature. We were unable to reach this goal under the time constraints of the semester and therefore failed to sell our product during the semester.

Although we didn't meet our goals in a semester's time, Brendan is eager to continue this project and make it his own and establish an LLC.

MVP Evolution[]

From a paper model to the real deal!

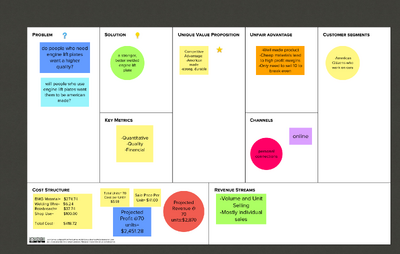

Final Business Model[]

Advice for Future MGT372 Students[]

Taking a class like Entrepreneurship does a lot more than teach you how to spell "entrepreneurship" it allows you to discover what you may be capable of in the business world of innovation and selling. Creating a brand new product is very difficult because, as consumers, we don't realize what new things we want until we see them. The creativeness of this course challenges you to find new and exciting ideas or to improve already existing ideas. That being said, here are some good pieces of advice for new MGT 372 students:

Another problem was innovating a product that was not "college friendly" put us behind because we were unable to sell to students, if any, like many of our classmates did. Another thing that didn't help us very much was selling the lift plates only through forums on the internet. It would have been beneficial if we were able to have our own website and also sell the lift plates to local shops around Harrisonburg. Without the LLC to cover our liability we were hesitant/unable to test innovations of new sales approaches because with our own interests in mind, we didn't want to make sales until we were legally covered.

Katie: MGT 372 is a really great class because of how realistic it is. Instead of sitting at your desk every class and getting lectured, you learn extremely valuable skills to use outside of the classroom. My three most important points of advice to future MGT372 students would be:

- start as early as possible and create lots of different little products that appeal to a variety of different customers

- even when you are not pursuing your main product be sure to try little things on the side to make any sort of many possible to fund your main product without getting too far behind when it comes to expenses

- find a product that appeals to college students because the majority of people around us are JMU students and if the product appeals to them you will be able to sell much easier

Brendan: Pick a business where you can pick up work instantly in your free time, I had to sit around all week and could only work on our project during the weekends, I was so busy working at the shop on weekends. Also, pick a product where the value equals the time you put into it, not the cost. In other words, chose something that you will only lose time over if you fail, not tons of money.

Andrew: 1. Start with a bunch of ideas, even ones that might seem ridiculous because even seemingly dumb ideas can be tweaked into something good. Keep an open mind.

2. Test the market early, meaning ask people if they would buy a product before making it and ask why they would or wouldn't buy it. Also ask what could be done differently and if they think the idea has merit.

3. Don't just create something and feel as though you have to stick with it. If it's bad and beyond saving, drop it. Don't waste your time and energy on a failing idea or product.