E-Z Lay Tanning Towels[]

About Us[]

Our team is made up of Adam Henne, JT Landy, and Courtney Minga. We are three entrepeneurs on the search for the next big thing. We came up with various ideas including Sockit socks with pockets, custom etched glasswear, and custom candles, but none of us were really all in on any of the ideas. From continuous research we came across what we thought to be an extremely simple, but very appealing idea. After a lot of brainstorming and customer discovery, we found that the EZ lay tanning towel would bring a twist to laying on the beach, quad, by the pool, or at a concert. When laying down anytime outdoors, it can always be a hassle searching for the perfect head rest; this is why we came up with a towel with a built in (but still removable) pillow.

In the preliminary customer discovery stages the EZ Lay team interviewed over 50 JMU students to get some feedback on the idea. Overall, reactions were extremely positive and helped us narrow our market focus to JMU girls moreso than guys.

The physical production on our first MVP was slightly delayed due to lack of sewing skills, but the EZ lay team quickly contacted Ragtime Fabrics for a sewing lesson. We were excited to find out that the production process will be rather simple and should not take more than 20-30 mins per 'EZ Lay' to make. For our first MVP, materials included: 2 white WalMart bath towels, 1/2 pillow case,1/4 mattress topper (pillow), and roughly 6 inches of Velcro tape. The overall cost to create the MVP was estimated to be about 12 dollars, and we feel that can be lessened even more when we produce on a larger scale.

Weekly Progress[]

Week 1, 2/4:[]

After some serious deliberation between ideas such as Sock-It socks with pockets, homemade candles, and iPhone cases we finally landed on a simple exciting idea of a tanning towel with a pillow built into it. When this idea came up we all jumped on board pretty quickly because of the potential market of JMU females as well as the fact that Courtney recently received a sewing maching for her birthday which allows us to save some money going forward with this idea. We decided to go over to Wal-Mart to buy some cheap towels and matress pad in order to start designing our minimum viable product. After doing some early customer discovery we decided to put our potential price between 15$-20$. Considering the prices for beach linens as well as pillows most people agreed that they would pay 20$ for the finished product. Also just to get our team venture going we set up a facebook page to continue getting the word out about our idea to our friends and other peers.

Week 2, 2/11:[]

Since we had a great resource already in Courtney's sewing machine, we decided to dive in and try to start doing some practice sewing.... 2 hours later..... the machine was barely threaded and we still had no idea what we were doing. The next day we called up Ragtime Fabrics to set up a sewing lesson and luckily it would only cost 15$.

First attempt at sewing...... fail.

All three members attended the sewing class, but Courtney acted as the main student. Thursday, we layed out the design which we decided would have one towel laying flat and another half-towel folded over (to make a rectangle) and sew together 3 sides leaving 1 open to insert or remove the pillow. We also brainstormed various mechanisms to close off the opening (to protect the pillow) such as velcro, zippers, buttons or laces, but none really seem practical enough. Courtney went was able to sew up a MVP to show to the class, but it is clear we still need much more practice with the machine.

Week 3, 2/18:[]

We bought some more materials to continue practicing with Courtney's machine and continued looking online for reasonably priced towels in colors that we thought would appeal to our market. Adam found a wholesale towel website that sold various towels in sets of 12 and we collectively decided to make a sort of big bet, and purchase 2 dozen towels for about 120$ that would potentially be our first sellable products. We created a new MVP which was our first completed product with the finished pillow included and also added a tying mechanism so that the towel would be easier to roll up and carry around. The mechanism was a two-way strap that was sewn on at the base of the towel, and when the towel part is rolled together with the pillow, the strap can be folded over and tied similar to a sleeping bag. We are still toying with ideas for a waterproof pillow case to prevent any damage to the inner pillow fabric, but have yet to find something in a reasonable price range to get the job done (Ragtime had waterproof micro fibers for over 20$ per square yard which would likely not even make 3 pillow cases). We continued reaching out to more customers and received 6 pre-orders from Courtney's sorority and got feedback from various other friends who really wanted to see the finished product.

Week 4, 2/25 -- Week 5, 3/4:[]

We are still waiting for our wholesale striped towel order to come in so we can get closer to beginning full scale production of our towels. Four more pre-orders were received in week 4 to be fulfilled after Spring break. We decided to rid of the strap mechanism because of looks and the fact that people were unsure of what our product was. Adam had multiple people joke around him carrying around a "pillow" because they were unsure of what the product actually was when it was tied up. The search continues for a waterproof or water resistant material to make pillow cases out of; we've come across some potential ideas such as a

Ragtime Fabrics-0

laminate table cloth material or just general plastic wrapping, but those materials are very thick and tough on the sewing machine which we can not manage to risk breaking. There has been continuous brainstorming of how we could get our product to reach more customers. A good potential idea was to talk to community pools that may want to buy some towels and rent them to pool goers. We should be able to start selling shortly after returning from Spring break.

Courtney attended another sewing class over Spring break to perfect her techniques and learn how to use some new stitching techniques to teach the rest of the team.

Week 6, 3/11:[]

We finally received our wholesale towel order three weeks after the order placement and the order came up 3 towels short, missing colors (including a color we most wanted), and proved to be less than stellar quality. In attempts to contact the towel supplier we were unsuccessful in resolving the problem. LESSON LEARNED - do not order from unknown suppliers unless you have contacted them first. Although we didn't get exactly what we expected, we felt the towels were of good enough quality that people would still want to buy them.

We then went on to have our first big production night making up 6 full towels while also preparing several more for sewing that would fill the pre-orders. Later that week Courtney was over at Wal-Mart and to her surprise there were tons of new beach towels just inside the door. For some reason or another we neglected to project the seasonal change in stores and for weeks struggled to find in-store beach towel alternatives around Harrisonburg. Fortunately, we could now open up to much more customization and color choices at a reasonable price with our crucial "partner," Wal-Mart. The lingering winter weather has been holding back our sales efforts, but we are hoping that will turn around within the next few weeks. Who wants to tan in the snow!

Week 7, 3/18 -- Week 8, 3/25:[]

We have continued to stockpile inventory with our newly found towels and only made a few sales to friends seemingly due to the weather. Also we have replaced the previous pillowcase with a light shower liner that is much less "crunchy" than prior materials we try. The liner is also much more durable and will likely never rip.

Adam and JT had their first sewing meeting when Courtney was not present this week and it was interesting to say the least. Week 8 we were able to get out to the quad and try to sell our product. Overall the first outing went well and customers really liked the idea, but most of the people we talked to either did not want to pay the price or did not have the money on them. Community pools should be opening within the next week or two; we are hoping to be able to sell to the residents and potentially the complexes themselves to rent towels to their residents.

Final Business Model:[]

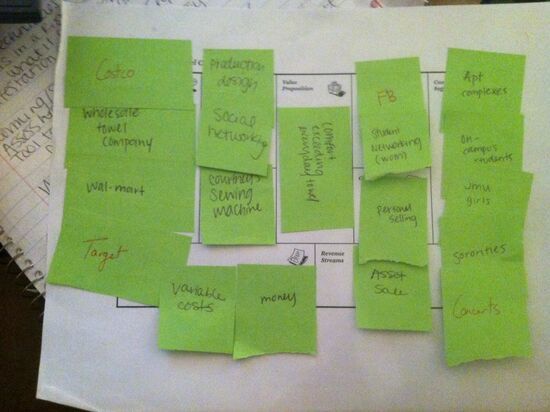

The business model was centered around our value proposition which was focused on comfort exceeding other outdoor lounging or tanning solutions and the idea of having a bed outdoors. Our customers were segmented into three main segments: JMU sororities, Harrisonburg apartment complex residents, and quad-goers. Other broad segments included JMU girls in general, and lakehouse/beach house familys/owners. Initially we thought it would be a good idea to sell a similar blanket type product for lawn attendees, but we were not confident enough to make another big bet so that never happened.

Our key resources first and foremost included Courtney's sewing maching. Luckily Courtney received the machine as a gift and we were able to have free access to it at all times which saved us a boatload of money (cost of sewing machine or professional sewing). Other important resources included the raw materials (towels, mattress topper, shower liner), startup money, and hours upon hours of time. In obtaining these resources and beginning our E-Z Lay production there were several key partners that helped us along the way as well. Our most important partners were Wal-Mart and Ragtime fabrics. They provided the majority of our materials along the way and helped us keep our input costs low (Target and Costco proved to be more expensive than expected). With these materials our cost structure per unit resembled the following: 1.5 Mainstays Beach Towels ($7), 1/4 MainStays Full size mattress topper ($2.50), 1/4 Light Shower Liner (1$) and miscellaneous overhead which we estimated to be about (1$) per unit. Selling at $20 per unit we were able to make a great profit margin and we were able to break even relatively quickly. Also, Ragtime provided sewing expertise in the earliest stages of our idea.

Sales channels only included personal selling of our product along with pre orders for custom colors if they were not in stock. With this, our one and only revenue stream came from physical asset sale. Complementary products such as low-dollar sunglasses were considered, but never implemented.

Word of advice for future MGT372 businesses...[]

Adam-

Like other big school projects (but more importantly for this one), get started early and do not procrastinate kicking off your business. It is important to put yourself out there early on and soak in as much information as possible; although we were successful in turning a profit, I feel we would have been much more successful if we got out of our comfort zones earlier in the process. Finally, listen carefully to all advice that Dr. Wales provides and take time to do the individual assignments; they will be more beneficial than you think and will help your business directly.

JT-

I feel that teams should aim to focus on products that are more easily marketable during their respective semester. For example, if it is fall semester, think of things that people will need to get ready for the winter. It was difficult to market beach towels when there was still snow on the ground. Another main piece of advice would be to just keep it simple in whatever you do. If you see a way to innovate on an original idea you may be successful, but keeping it simple will for sure help in the long run.

Courtney-

When Dr. Wales says it's time to get started and get moving...listen to him! It is extremely tough to find the balance between your other classes and working on your ventures, especially when there is a time crunch. Therefore, you must start early and get the ball rolling. Also, find something that you will enjoy. Our product was pretty cool and we definitely filled a need; so find something that you can be proud of, and maybe even use yourself! Also, I would suggest making a schedule, so every week you have a set time to work on your ventures; the more organized and proactive you are, the easier and more successful your venture can be.