Members on our team are Yesenia Jimenez, Sara Garrettson, Josh Winks, and Jin Lee. The product we are going to sell is a fabric phone case that holds credit cards and protects/cleans your screen. These cases will come in different prints and styles and will accomodate different kinds of smartphones.

Week 1 (February 3 - 9)[]

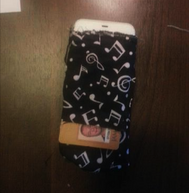

One out first week, we brainstorm plenty of ideas worth pursuing. We came up with many ideas and narrowed it down to tie-dye shirts and phone cases. Our first prototype of phone case was constructed with recycled plastic bottles fabric (to be eco-friendly) from Micheals. It was very rough and held together with crazy glue (tie-dye picture on the right). We also made sure to add a pocket in the back where credit cards may go. We made the pocket really long and not wide enough. (This was just to get idea of how it may look).

Protype

Week 2 (February 10 - 16)[]

We were excited to finally bring our project to life. We made a survey online to see which was the most popular phonecase style. We than decided to first go shopping. We visited many stores such as Walmart, Bed Bath and Beyond, Fabric stores, and Micheals to compare prices for sewing machines. The prices were extremely high! So we decided to buy a small sewing machine from Micheals. Now, our next mission was to begin sewing. None of us really know how to sew or even use a sewing machine so we took our time to know where threads go and how to get the machine to work.We then sewed a series of rough prototypes. It was a very difficult and time consuming task. The first case we did we accidently sewn the pocket upside down! (as you see on the picture on the right). We were so close to finally getting it down and made a silly mistake! It started to become frustrating. The second attempt had unfinished hems. We attempted to try one last time to finish the week off. Finally! we had a case done when we went to put the phone in it, it was to small! Unfortunately, our measurements were quit off. Jin decided to ignore the sewing machine and do one by hand (polka dot picture on the left). This case looked the best.

Week 3 (February 17 - 23)[]

Because we are having such difficulties learning to sew we realized it may be easier to just consult a tailor. Sara also brought her larger sewing machine (professional one compared to our cheap Micheals-small one). This sewing machine had far more options and buttons which proved to be very challenging to learn to use. Going to the tailor will save us lots of time that would've spent learning to sew or on us sewing the cases ourselves. We also decided we are going to prepare to make green tie dye items for St. Patrick's Day which is coming up in about a month.

Week 4 (February 24- March 2)[]

Yesenia and Sara spent the afternoon searching for tailors around the area. After going to talk to many tailors around the harrisonburg area it does not look promising. Tailor each suggested an average price of $10-$15 to to make one! (we'd also have to provide fabric) so we decided it would be too expensive. This week Sara and Josh went to Ragtime Fabrics (downtown) and took a sewing class. In the class we learned how to properly use a sewing machine. We also worked on several designs for a phone case. We cut out material and worked to make one. Sara stayed longer and work on sewing and finishing off a case. Now that the basic sewing skills are known we can now begin to make our product, we hope.

Week 5 (March 3- March 9 Spring Break)[]

Yesenia worked on a new product over springbreak. This product consists of bobby pins, wire, earring hook, and nail polish. While experimenting Yesenia learn through practice a way to make it simpler to paint. By using an envelope, you align 8 bobby pins (8 on each earring- makes it look fuller and appealing) and paint them all white so the next coat will look good. After painting them all white you can go back and paint any design you'd like. When it comes to dealing with the wire, it took practice to get the earring part to all be the same size but as time went by it became easier. Yesenia successfully sold 6 pairs over break. Josh continued to work on the laptop cases and successfully sewn 14.

Week 7 (March 16- 22)[]

After the struggles and time we've spent on the phone cases and laptop covers we decided to end this journey. It was too time consuming and difficult to make. So we decided to pursue the earring idea more thoroughly, we started making more pair. The profit margins for the earrings were way higher than the phone cases and laptop covers so to us, it only made sense. (We sold each pair for $5, Cost=300ct bobbypins $2.49, Earring hook (60ct) $1, wire $1 total cost=4.49 to make 19 pairs) This week we have booked a table in showker lobby for next week to sell our products. We've also agreed on a name for our team, HandyCrafts.

Week 8 (March 24-30)[]

We had a table and it was a complete fail in Showker. We learned that times 12pm-2 wasn't a good time. There was barely any traffic of people. We also plan to make a poster so people will know what we are selling and approach us. Sara called Walmart and set up a table for April 18.

Week 9 (March 31- April 6)[]

There was little work done by the team due to the large amounts of work and time that had to be devoted to other classes. We are continueing to the sell earrings already made and Yesenia managed to sell 5 pairs this week

.

Week 10 (April 7 - April 12)[]

On April 10th Sara ordered some start up ingredients for hair chalk. These include pigment, kaolin clay, arrowroot powder, and witch hazel. The recipe calls for:

2 tbs. colorant (avg $3.32/oz.)

1/2 tsp. kaolin clay ($2.40 for 12 oz.s)

1/2 tsp. arrowroot powder ($4/lb.)

1/2 tsp. water

1 tbs. witch hazel (about $2 per bottle)

Also Sara went to the fire martial to get approval to set up at Walmart

Week 11 (April 13- 20)[]

Ordered more product We made some progress this week. Jin sold 3 laptop cases. Also, we had the table set up at Walmart to sell our products. The day was very windy and a little bit chilly.

Safda got fliers for Hair Chalk approved.

Sara has started a new project with hair chalk.Hair chalking is an easy, quick and inexpensive way to add temporary color to your hair. You can do it yourself without making a big commitment. She has also made some serious progress with the hair chalk idea and tried to get approval to sell it in schools. Unfortunately there was a bomb threat at her high school so it didn't work out. She did however sell at her brother's lax practice fields to the little girl's teams and sent out a mass email to the parents of the kids at her brother's school. This is where we got the most success! Initially the prices started out at $5 per stick but then increased to $6 and a pack of five increased from $15 to $20. This is because the first batch Sara made with her mother were small "stones" and then once we figured out how to do it better we made them bigger and better. Sara was extremely fortunate to be able to use the scanning and copying machines at her father's office to print out fliers and labels.

Week 12 FINAL WEEK (April 21-27)[]

We have finally reached the ending of the semester. This week we will continue to sell the products we have already made and work on a video to show everyone our journey.

The Begining[]

We began in our group seeking a venture where we could make something ourselves with relatively inexpensive materials. We decided to begin by creating fabric phone covers with a pocket for a JAC card, driver's license, or credit card. This gave us many possibilities. We had different fabrics we could use, different configurations, different styles, and fiting different phones. We used feedback from the class and friends and attempted to make one. We had extreme difficulty using a sewing machine so the first one got glued together. Now that we had a very rough MVP we began getting more feedback. We heard that the fabric was too coarse, so we switched from felt to real fabric. People also liked ones that had a flap to secure the phone and the card. When getting feedback almost exclusively girls were interested in the product, specifically college girls. We continued to work on this but the lack of sewing skills really was hurting us. Sara and Josh took a sewing class and actually learned how to sew using a sewing machine. At the class, they got told the sewing machine we bought was more for children and would not do the job. However, the trip was a valuable learning experience. At this point in class, Torey (classmate) mentioned how he wanted a laptop case not a phone cover. Josh took a look into this idea. He found that it wasn't easy to find a JMU colored laptop case. So over spring break he worked to make 11. Unfortunetly, our first set of ventures hit a snag when we realized that it took much longer to make these than we ever thought. It was very difficult and time consuming. It took about an hour or more to make a really nice laptop case or phone cover. It took all break for Josh to make 11 laptop cases. The time to do this just made the ventures not very profitable in the long run and the protoype phone covers never got sold. We did manage to sell 6 laptop cases, though.

Our Second Group of Ventures[]

After the phone and laptop covers did not really pan out, we decided to brainstorm some other ideas. We still had our tie dye idea that Sara was working on. Yesenia came up with bobby pin earrings.Yesenia started making the earrings and Sara worked on the tie dye. The bobby pin earrings were made from 8 bobby pins painted with nail

polish in a pattern and bright colors. Yesenia's idea started to gain more traction. She sold several pairs to her friends, family, and classmates. Girls also complemented her on the earring when she wore them around. This idea was appearing very promising until the sheer profit per item was low. We'd have to make over 100 pairs to reach our goal. We had great profit margins but very little time to sell. The other issue was that the time to make a pair was half an hour. This time was mainly to carefully paint a design. After first painting the white coat we must let it dry to get the next coat on. We did not think that we could make that many pairs by the end of the semester let alone sell them. We spent more effort on the earring due to their demand over the tie dye that was less demanded. Yet, again we were looking for a winning idea.

Our Final Attempt[]

Sara came up with an idea to sell hair chalk. It is made out of a few simple ingredients: pigment, witch hazel, arrowroot powder, water, and kaolin clay. Each brick costs about a dollar to make and sells for $6 a piece individually. She ordered all the ingredients from online but made the hair chalk at home in her kitchen at NOVA. The hair chalk can be applied to one's hair and it temporarily colors your hair. This was great because the weather was warmer now.Hair chalking is an easy, quick and inexpensive way to add temporary color to your hair. After a day the chalk can be washed out. The yellow chalk even glows under black light. The advantage of the chalk over dye is that it's temporary. It allows girls, primarily, to color their hair for just an evening to go to a party or put a colorful streak in. We wished we had more time to investigate this idea. We only came up with this idea with a few weeks left and decided to give it a try. One of the difficulties of it is, just getting the supplies to make it. It took several weeks to just get the supplies. We basically had to sell the idea to people and not a product until we actually had some to make. The best part of this is that the finished product can only be found online and most people aren't very aware that it even exists. We wish we had more time to explore this opportunity because this seems less complex to make and fairly popular with consumers. The age range among girls was also much larger. Even young girls, like 8 or 9 would enjoy a colorful streak in their hair for summer and their parents know that it will wash out.

What We Learned[]

We all learned that entreprenuership isn't easy. It takes a lot of hard work and some luck. We learned and really tried to embrace in our group the idea of little

bets. Make just one or two prototypes and get feedback or see if someone will buy them. It was very easy to see how a big bet will mess you up. It locks you in and you don't want to give up on sunk costs. However, we really tried to just kept trying. We did manage to make profits, $260, but did not hit our goal. Part of entrenuership is to deal with failure and I think we handled this well. Not dwelling on what went wrong, but what we were doing right too. Also, getting feedback from customers and people was very important!

Among just entreprenuership skills we did learn to practical skills too. Our team would likely never have learned to use a sewing machine if we didn't buy one or having Sara and Josh take classes. We learned how to work with fabric, work with wire, and make chalk. These may seem irrelevant, but it's just another skill we now have.